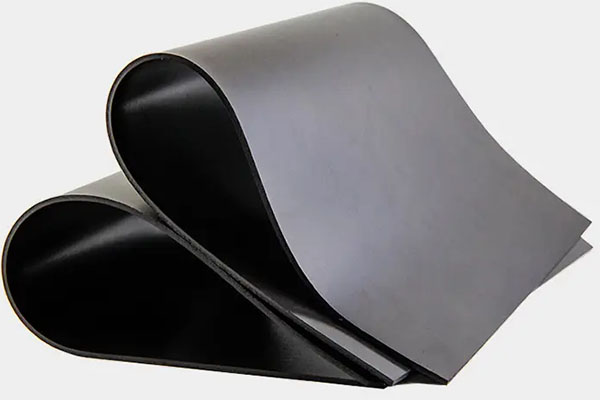

Lẹhin sisẹ, apẹrẹ jẹ rọ, rirọ, ati bendable, ati pe apẹrẹ le ṣe gige ni ibamu si iwọn ti a beere, ati pe o tun le bo pelu PVC, alemora, ati epo UV gẹgẹbi awọn ibeere pataki alabara.

Idanwo iṣẹ ṣiṣe rẹ ni gbogbogbo pẹlu irisi, iwọn, awọn ohun-ini oofa, polarity oofa, lile, walẹ kan pato, agbara fifẹ, resistance ti ogbo, iṣẹ iyipo.

Awọn anfani rẹ wa lori aitasera ti o dara, iṣedede iwọn giga;ipa ti o dara ati idena gbigbọn, ko rọrun lati fọ;kekere walẹ eyi ti o jẹ conducive si awọn lightweight ti awọn ẹrọ ati gbogbo ẹrọ;O le ṣe iṣelọpọ sinu oofa pẹlu radial kikun (itọpa kikun) iṣalaye, ati pe o le ṣe iṣelọpọ pẹlu awọn ọna oriṣiriṣi awọn eefa bii awọn apẹrẹ gigun ati tinrin, ati nigbati iṣẹ lẹhin-iṣẹ bii ofo, gige, punching ati atunse le ni irọrun ṣe ni irọrun. .

Alailanfani rẹ ni pe magnetism jẹ alailagbara pupọ, ati pe agbara oofa bẹrẹ lati kọ silẹ ni 100 ° C, yato si, oofa roba ni ọpọlọpọ awọn nkan irin bii neodymium ati irin, eyiti yoo jẹ ibajẹ ati ipata ninu afẹfẹ, ati awọn iwọn otutu abuda ni o jo ko dara, ati awọn ti o jẹ rorun a pulverized.

O ti wa ni lilo ni akọkọ ni awọn edidi Tii lori awọn ilẹkun firiji, awọn apoti ohun ọṣọ disinfection, awọn apoti ohun ọṣọ idana, awọn nkan isere, awọn ohun elo ikọwe, awọn ipolowo, awọn ẹrọ afẹfẹ itutu agbaiye kọnputa, awọn ẹrọ ipese afẹfẹ ti afẹfẹ, awọn ẹrọ atẹwe itẹwe, VCD ati awọn ọkọ ayọkẹlẹ awakọ DVD, afẹfẹ DC ti ko ni wiwọ (ikedi ) awọn onijakidijagan, awọn edidi ilẹkun oofa, awọn ohun ọṣọ, awọn matiresi oofa ti itọju ilera, awọn ọpá oofa, ami wiwakọ ipese magnẹti fun awọn ọkọ irin ajo, Awọn fifi sori ẹrọ mimu fun awọn elevators (ni iṣe gbogbo awọn elevators lo awọn iwe itọju), Ohun elo ikọwe ati awọn ẹru tuntun (o dara fun awọn nkan ibatan gbogbo eniyan).

Ti ara Properties Of roba Magnet

| Iwọn otutu Curie (℃) | 100 |

| Iwọn otutu iṣẹ ti o pọju (℃) | -40-80 |

| Hv (MPa) | 33-38D |

| Ìwúwo (g/cm3) | 3.6-3.8 |

Sisan iṣelọpọ

Ayẹwo ohun elo

Ohun elo Dapọ

Banburying

Fípalẹ̀

Extruded Molding

Ayewo ati apoti

Atọka iṣẹ ṣiṣe ohun elo ti oofa roba

| Awoṣe | Ọja Iru | Iṣẹ iṣe oofa | Ohun-ini Ti ara | ||||||||||

| Br | BHc | Hcj | BHmax | Agbara Agbara | Lile | iwuwo | Iwọn otutu. | ||||||

| mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m³ | MGOe | kg/c | A | g/cm³ | ℃ | ||

| DMS001 | Isotropic extrusion oofa rinhoho | 140-180 | 1400-1800 | 105-130 | Ọdun 1320-1635 | 160-238 | 2010-3000 | 4-6.4 | 0.5-0.8 | ≥20 | ≥90 | 3.6-3.8 | -40-85 |

| DMS002 | Ologbele-anisotropic extrusion oofa | 180-210 | 1800-2100 | 130-151 | Ọdun 1635-1900 | 175-286 | 2200-3600 | 6.4-8.8 | 0.8-1.1 | ≥20 | ≥90 | 3.6-3.8 | -40-85 |

| DMS003 | Isotropic colendering roba oofa | 180-220 | 1800-2200 | 111-143 | 1400-1800 | 143-191 | 1800-2400 | 5.6-8.8 | 0.7-1.1 | ≥20 | ≥95 | 3.6-3.8 | -40-85 |

| DMS004 | Anisotropic extrusion oofa rinhoho | 210-250 | 2100-2500 | 151-179 | Ọdun 1900-2250 | Ọdun 191-319 | 2400-4000 | 8.8-12 | 1.1-1.5 | ≥20 | ≥90 | 3.6-3.8 | -40-85 |

| DMS005 | Ologbele-anisotropic colendering roba oofa | 220-240 | 2200-2400 | 128-151 | Ọdun 1600-1900 | 159-207 | 2000-2600 | 8.8- 11.2 | 1.1-1.4 | ≥20 | ≥95 | 3.6-3.8 | -40-85 |

| DMS006 | Anisotropic colendering roba | 240-270 | 2400-2700 | 151-179 | Ọdun 1900-2250 | Ọdun 191-238 | 2400-3000 | 11.2-13.6 | 1.4-1.7 | ≥20 | ≥95 | 3.6-3.8 | -40-85 |

| DMS007 | Itanna mọto ina 500# | 240-270 | 2400-2700 | 151-179 | Ọdun 1900-2250 | Ọdun 191-238 | 2400-3000 | 11.2-13.6 | 1.4-1.7 | ≥15 | ≥95 | 3.6-3.8 | -40-85 |

| DMS008 | Itanna mọto ina 300# | 240-265 | 2400-2650 | 151-179 | Ọdun 1900-2250 | Ọdun 191-238 | 2400-3000 | 11.2-13.2 | 1.4-1.65 | ≥15 | ≥95 | 3.6-3.8 | -40-85 |

Aworan Ifihan

-

Awọn apejọ Oofa pẹlu NdFeB, SmCo, AlNiCo ati ...

-

Dina NdFeB, ni gbogbogbo ti a lo sinu moto laini...

-

Yika NdFeb, ni gbogbo igba loo sinu electroacou...

-

Awọn apẹrẹ NdFeB miiran, gẹgẹbi apẹrẹ akara, iho-s ...

-

Apa NdFeB, ni gbogbogbo ti a lo sinu ina mọnamọna ...

-

Oruka NdFeB, ni gbogbogbo lo sinu agbohunsoke